Contact Us

E-mail:

begita_machinery@126.com

Phone/WhatsApp:

+86-13959953903

Address:

No.82, West Road, Wushan Industrial Zone, Anhai Town, Jinjiang Quanzhou, Fujian, China.

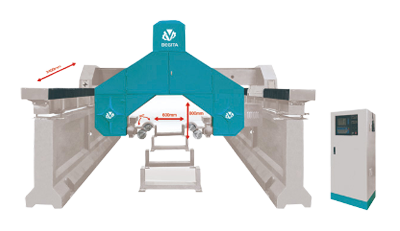

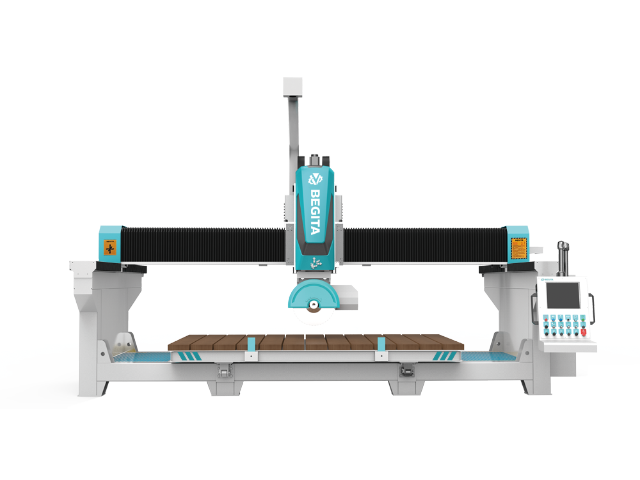

Bridge Type Cutting Machine

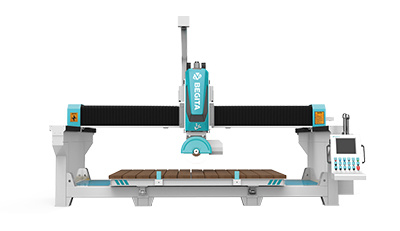

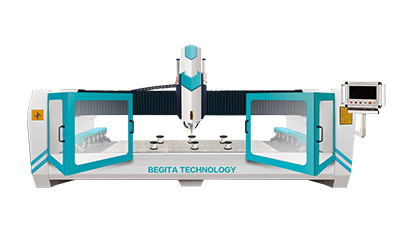

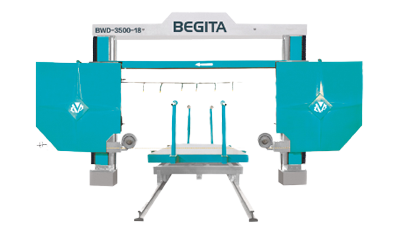

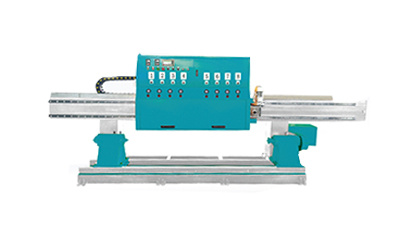

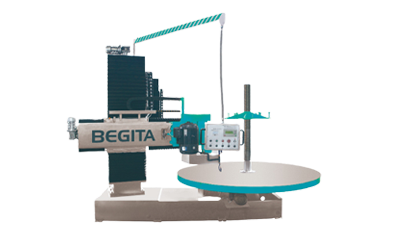

Monoblock bridge cutting machine

This integrated CNC bridge cutting machine combines robust construction with intelligent control for unparalleled precision in stone processing.

Core Features:

User-Friendly Microcomputer System: Simplifies operation for maximum efficiency.

Rigid Monoblock Design: Ensures easy installation and foundational stability.

Precision Engineering: The main frame is milled in one pass on a CNC gantry center, supported by high-end linear guides, ball screws, and servos.

Guaranteed Performance: This synergy delivers exceptional accuracy, stability, and productivity for high-value, large-format slab processing.

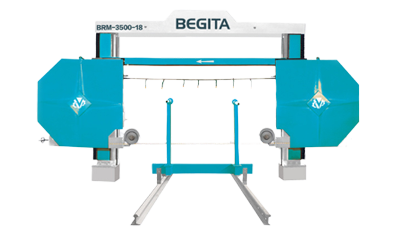

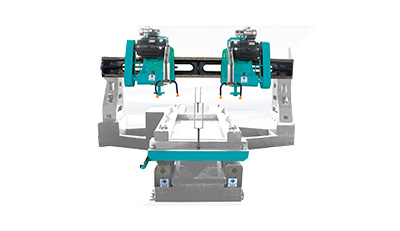

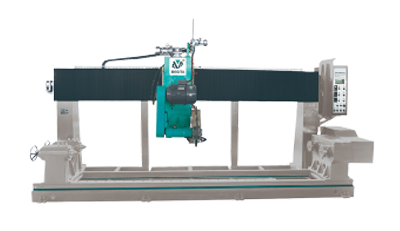

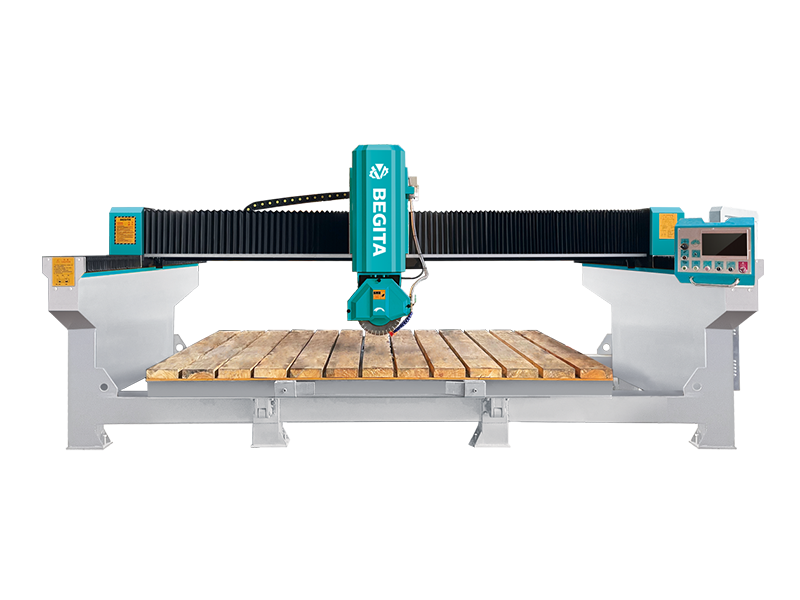

Integrated Bridge Cutting Machine for Granite Marble Stone

It adopts PLC system and human-machine intelligent operation interface. The main engine uses double hydraulic lifting to combined with chrome guide sleeve, which is small clearance and wearable and beautiful. The design of multi-layer seal in the guide sleeve is waterproof, dustproof and leakproof. The sidebeam adopts high precision linear slide track.

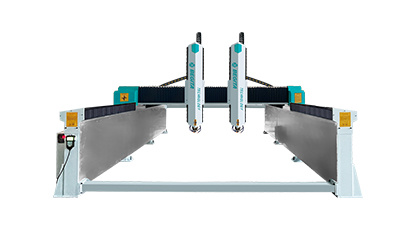

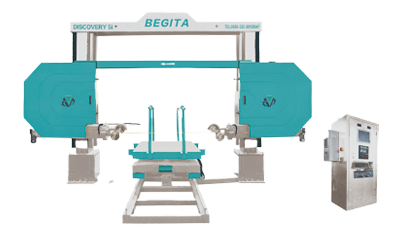

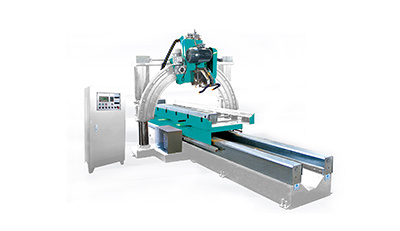

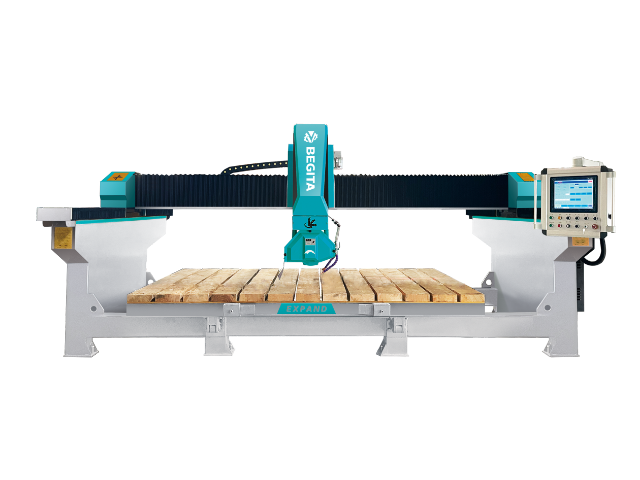

This 5-Axis Bridge Cutting Machine is a powerhouse of efficiency, designed to streamline your stone processing and boost profitability.

Key Advantages for Your Business:

Unmatched Versatility: Perform complex tasks like 3D sculpting (wash basins, fan shapes, profiled edges) on a single machine, eliminating the need for multiple dedicated units.

Zero-Interruption Production: Features a bus-based absolute value servo with power-off memory, allowing jobs to resume instantly after a stoppage, saving time and reducing material waste.

Built for Precision & Uptime: High-precision linear guides, ball screws, and a robust oil-immersed structure guarantee flawless accuracy and minimal maintenance, ensuring continuous production.

Space-Saving & Easy to Use: Its compact footprint and simple operation reduce facility costs and training time, allowing you to get up to speed quickly.

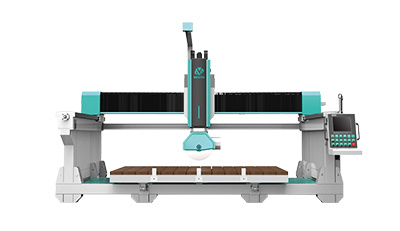

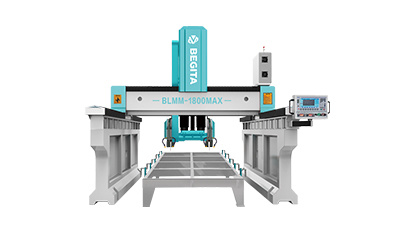

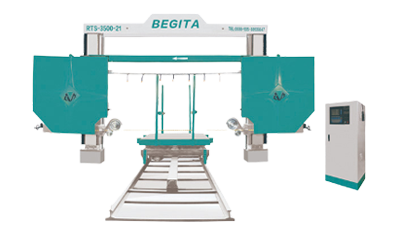

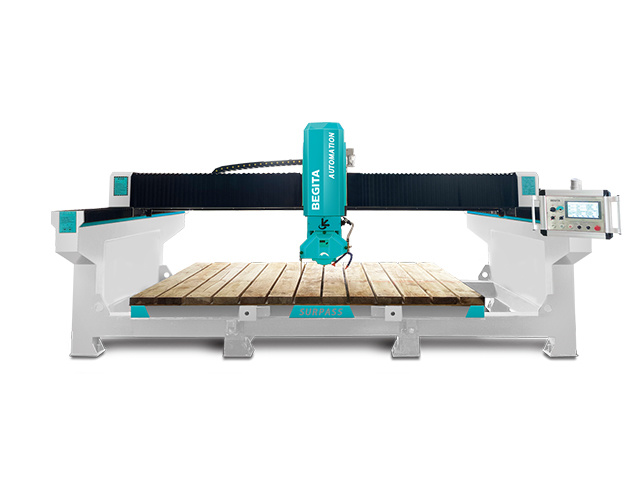

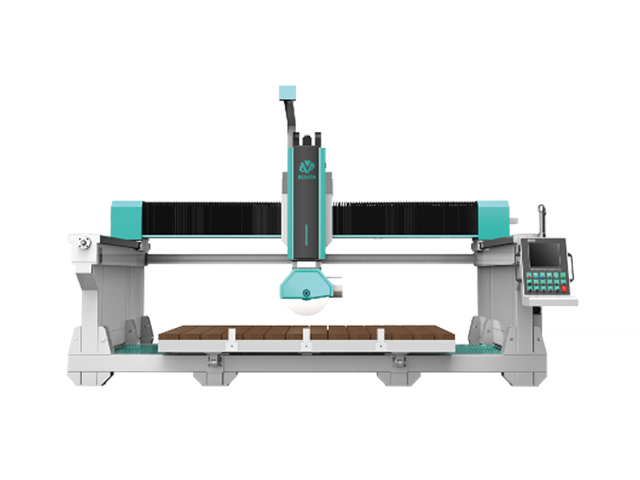

Bridge Integrated Cutting Machine(Special for Marble、 Sintered Stone and Quartz Stone)

This machine adopts Microcomputer system, easy to operate;Integrated structure, easy to install;The frame of the machine body is processed and formed by CNC gantry milling center at one time, using high-precision linear guide sliders, grinding-grade ball screws.It greatly improves the stability, processing accuracy and production efficiency of the equipment.It is suitable for all kinds of large-scale plate processing with high precision requirements and high value.

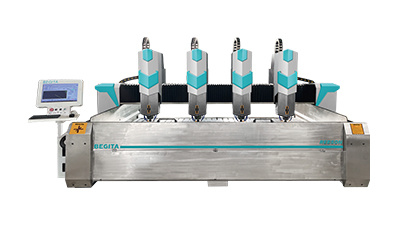

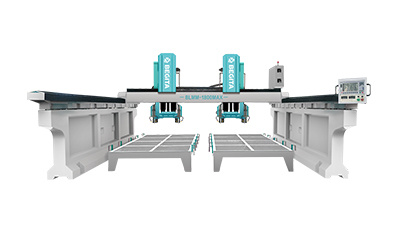

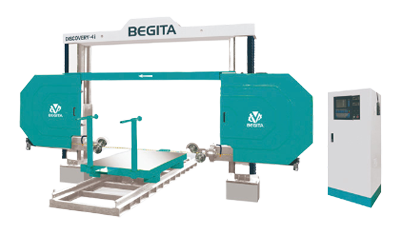

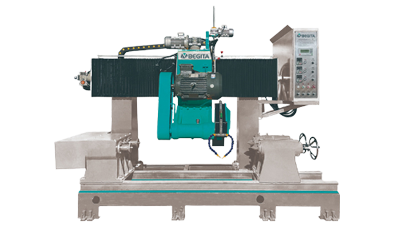

4 Axis bridge cutting machine adopts four-axis linkage CNC system control, bus absolute value servo (with power-off memory function), high-precision linear guide, ball screw drive, oil-immersed track structure, with multi-function, high precision and strong stability and other advantages.

5 Axis Bridge cutting machine adopt 5 Axis linkage CNC System Control, Bus-based absolute value servo (with memory function for power off), high-precision linear guide rail, ball screw transmission, oil-immersed track structure, with multi-function, high precision, strong stability and other advantages. Its processing functions include: arbitrary-shaped lines, fan-shaped plates, wash basin and special-shaped edge profiling, etc. The equipment has multiple processing functions, wide application, small space, and simple operation. It is a great equipment for stone processing.

Bridge Integrated Cutting Machine for Marble Sintered Stone and Quartz Stone

This integrated CNC bridge cutting machine combines a rigid one-piece frame with premium components to deliver the ultimate in stability and precision for high-value, large-format slab processing.