Share to

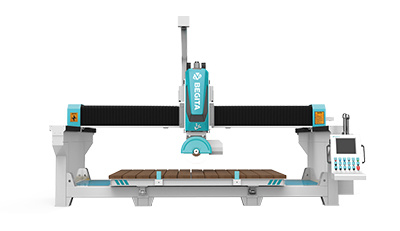

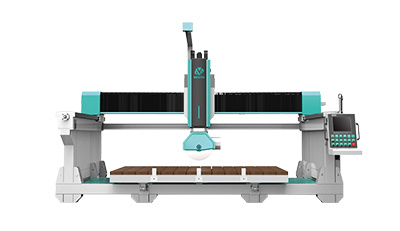

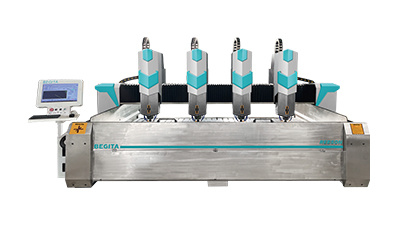

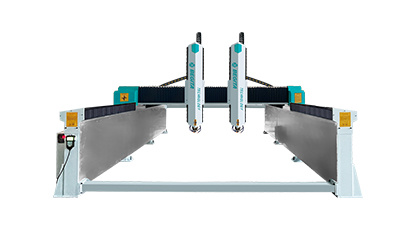

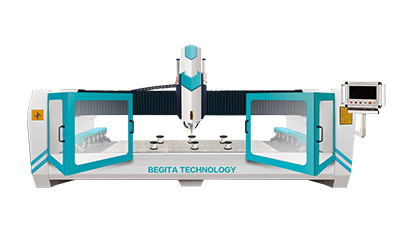

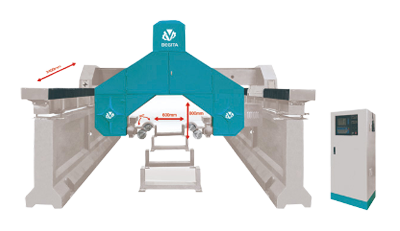

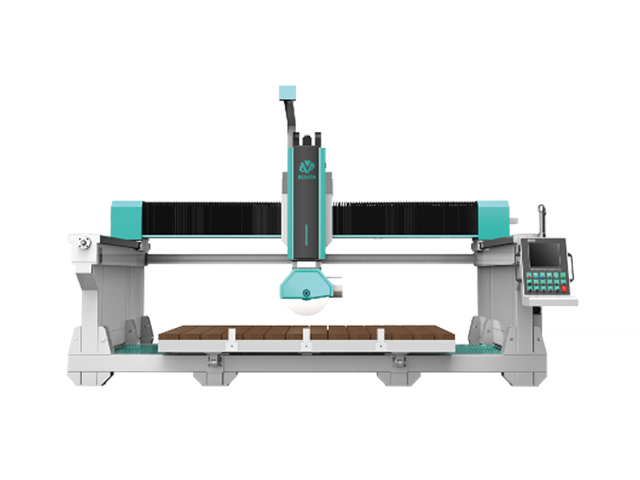

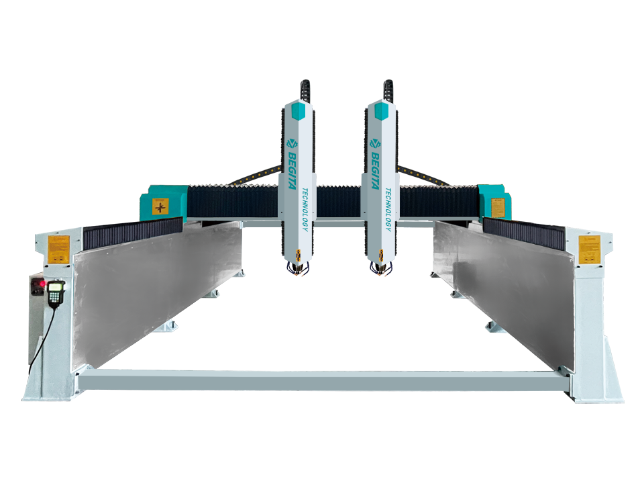

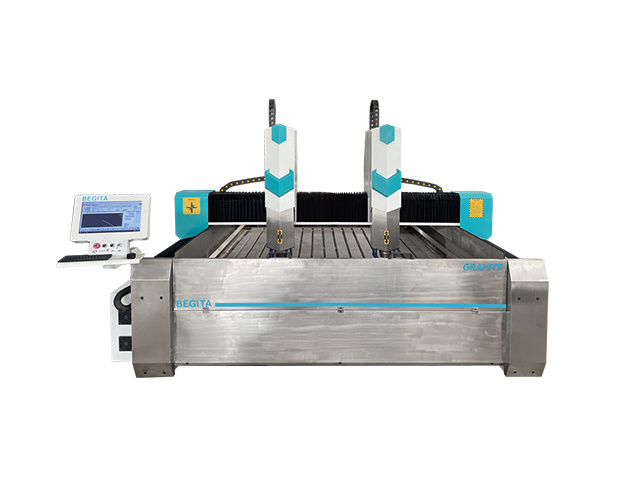

5 Axis Bridge Cutting Machine

Model:Create 450

Still deciding? Interested, Contact US !

View similar products

Tag list

Product Introduction

This 5-Axis Bridge Cutting Machine is engineered for supreme precision and versatility in stone processing. It operates under a sophisticated 5-axis linkage CNC system, driven by a bus-based absolute value servo system with built-in memory for uninterrupted operation after power-offs. The machine integrates high-precision linear guideways, ball screw drives, and an oil-immersed track structure to ensure exceptional stability and longevity. Capable of producing arbitrary shapes, fan-shaped plates, wash basins, and complex edge profiling, it consolidates multiple processing steps into a single, streamlined operation. This multi-functional design minimizes the factory footprint while maximizing output, delivering significant gains in productivity and substantial cost savings for modern stone workshops.

Technical Parameter

| Parameter | Unit | Create 450 |

| Blade diameter range | mm | Φ350-Φ450 |

| Max processing size | mm | 3200×2000×100 |

| Lifting stroke | mm | 300 |

| Worktbale size | mm | 3200× 2000 |

| Table tilting degree | ° | 0~85° |

| Head rotating degree | ° | 0~360° |

| Head tilting degree | ° | 0~90° |

| Air speed | m/min | 15 |

| Repeated accuracy of positioning | mm | < 0.1mm/1000 |

| Main motor | kw | 18.5(Permanent Magnetic Synchronous Motor) |

| Gross power | kw | 26 |

| Water consumption | m³/h | ≈3 |

| Outline dimension | mm | 5600×3600×3500 |

| Gross weight | kg | ≈6000 |

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!

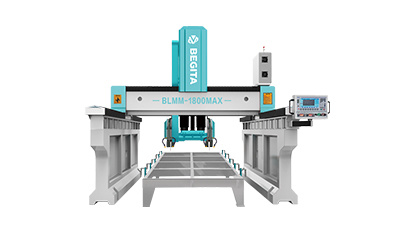

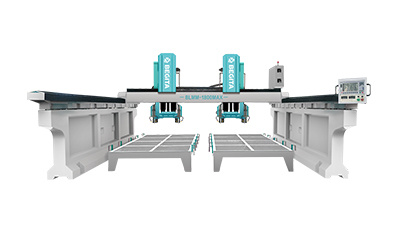

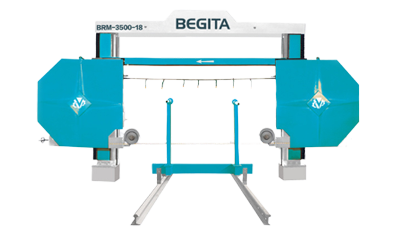

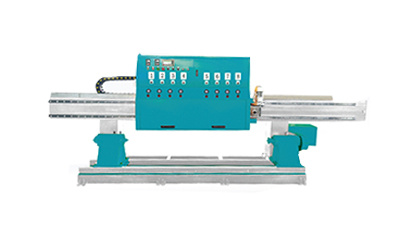

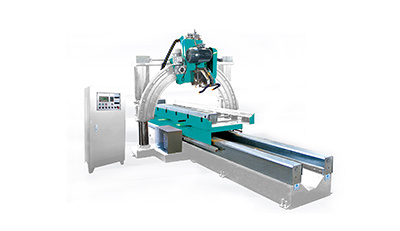

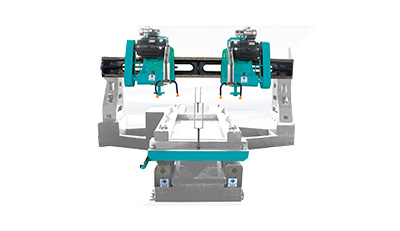

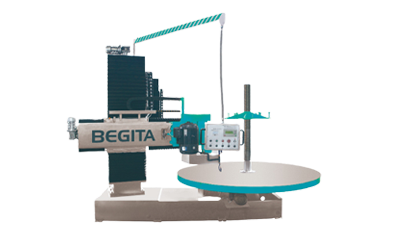

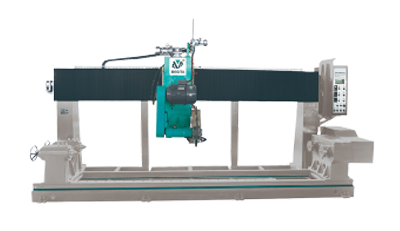

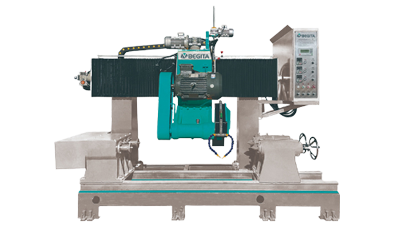

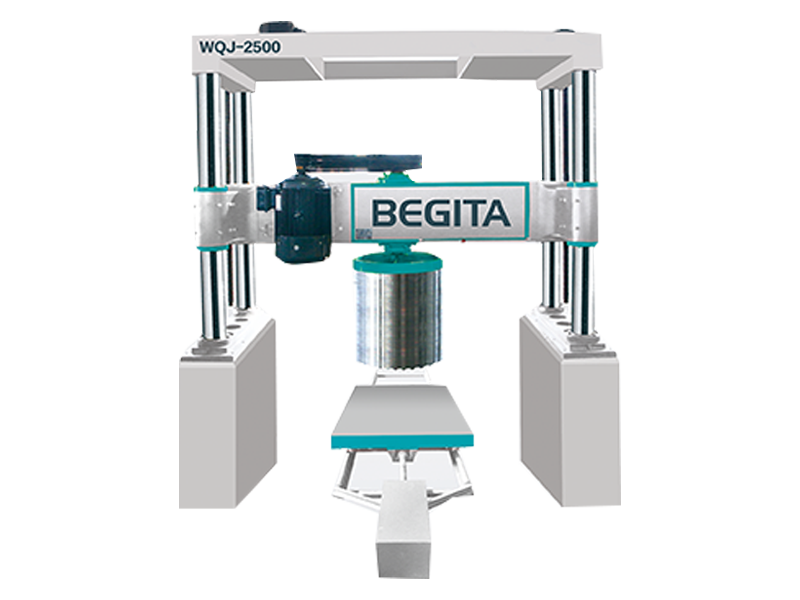

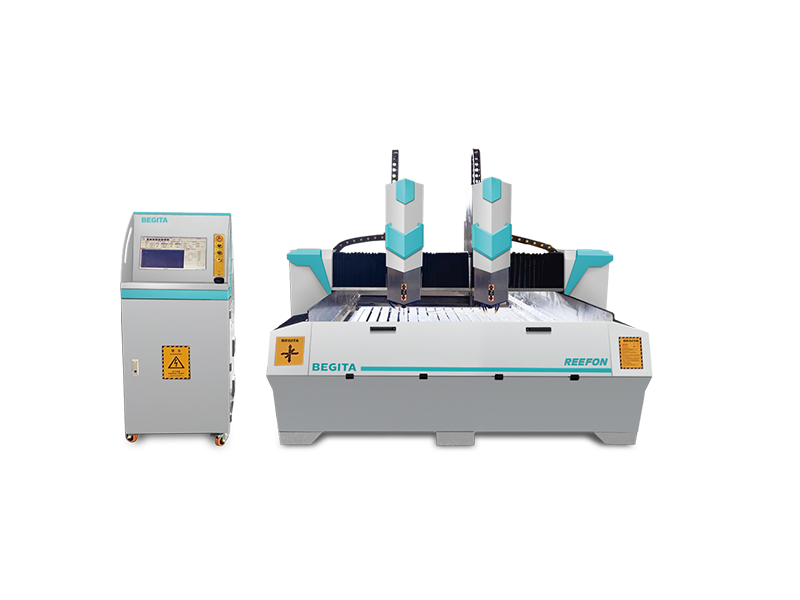

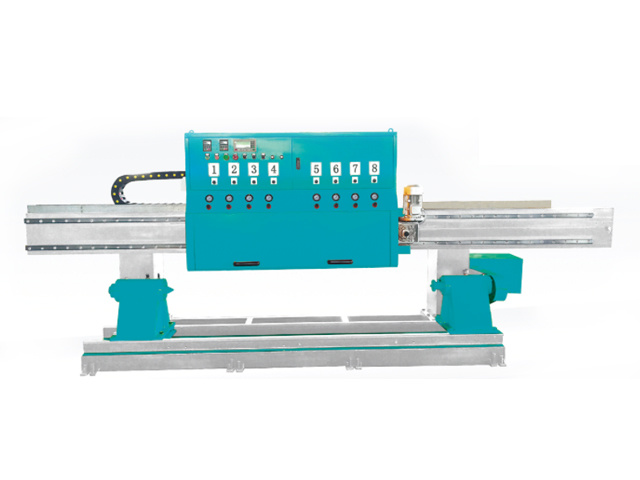

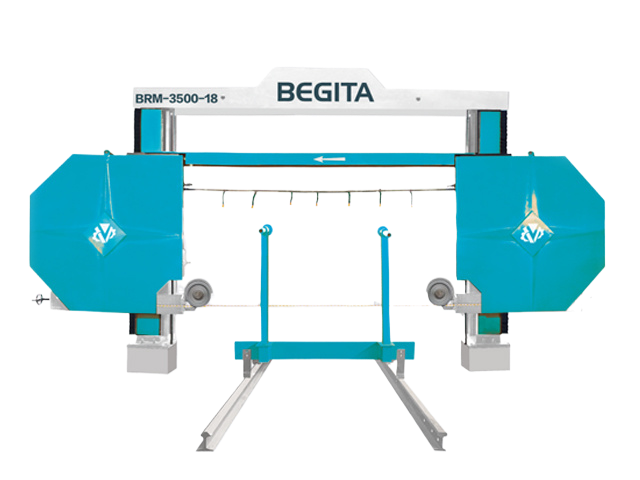

Related Products